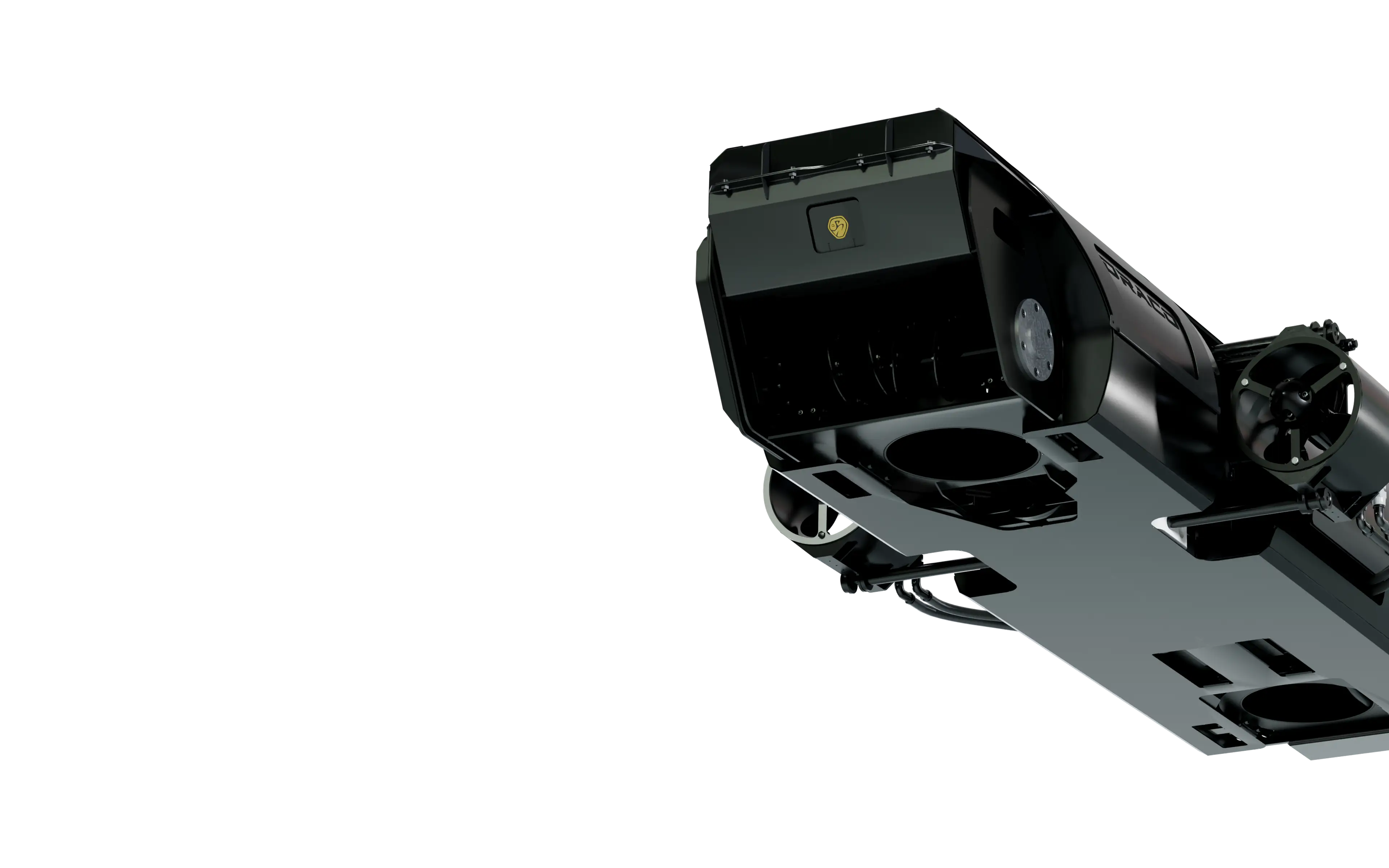

Online Oil Tank Cleaning Robot

The Challenge & Vision

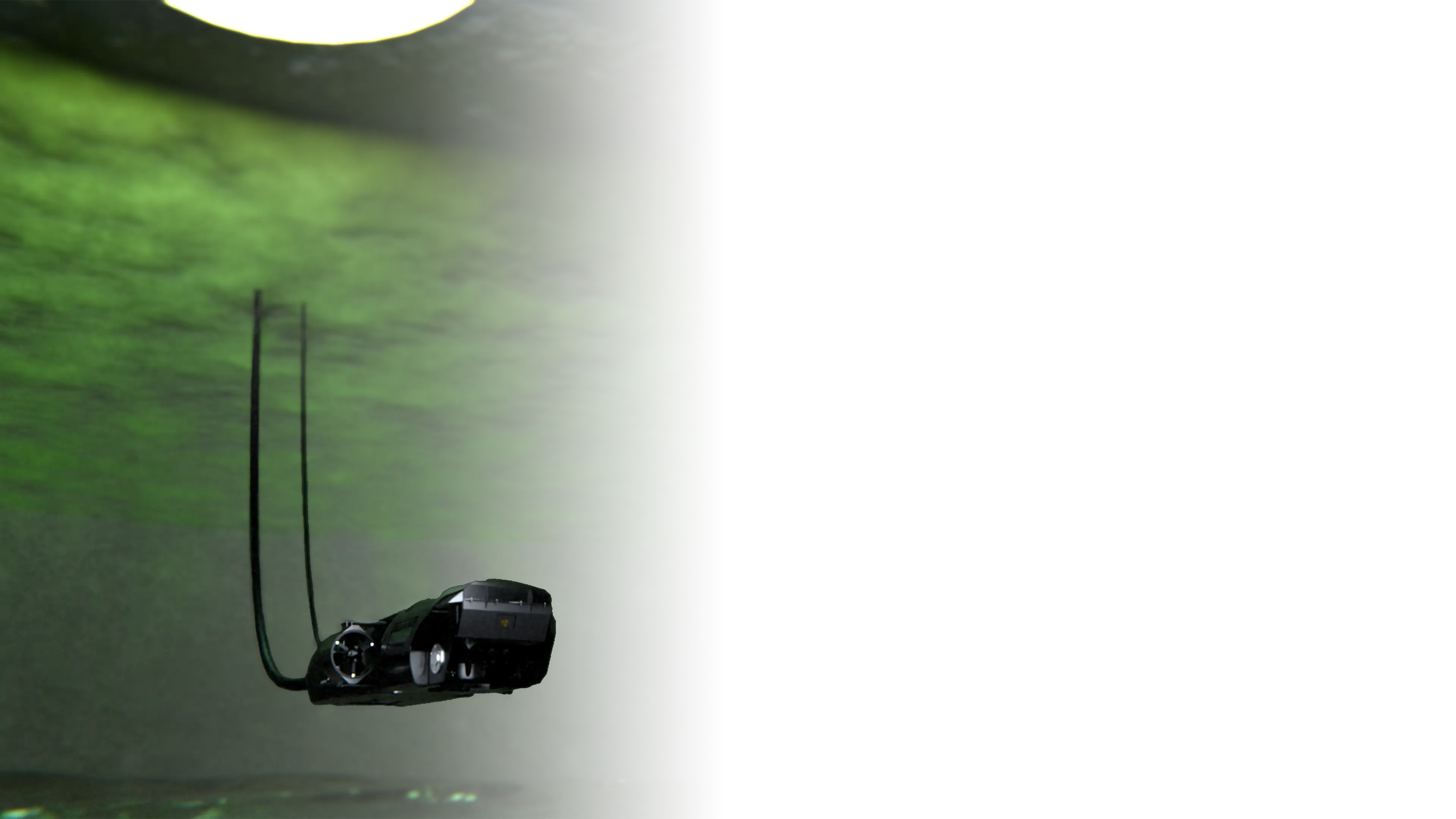

The Draco project is critical for the Oil & Gas sector, targeting the enormous operational challenges of cleaning hazardous industrial storage tanks. Draco is engineered for online operation, meaning it can perform cleaning while the tank remains active, significantly reducing downtime and maximizing human safety.

Key R&D Breakthroughs:

- 1.Chemically Inert Materials: Developing specialized alloys and composite casings for high resistance to corrosive hydrocarbons and volatile environments.

- 2.Non-Stop Operation System: Designing autonomous navigation and cleaning routines to ensure continuous, reliable performance within the sludge layer.

- 3.Acoustic & Thermal Monitoring: Integrating advanced sensors for real-time diagnostic reporting on tank integrity from the inside.

Technical Specifications

Environment Rating

ATEX Zone 0

(Target)Cleaning Method

High-Pressure Hydro-Jetting

Material

Corrosion-Resistant Composites

Development Roadmap

Draco's development is centered around safety, material science, and guaranteeing non-stop operational performance in highly hazardous environments.

Phase 1

Material Science & Containment (Completed)

Selection and rigorous testing of chemically inert materials, focusing on intrinsic safety and explosion-proof component design.

Phase 2

Scaled Prototype (Current)

Development of a full-scale mobile prototype, stress testing the mobility systems within complex sludge layers and fluid circulation dynamics.

Phase 3

Online Operations Simulation (Future)

Comprehensive validation of cleaning efficiency and non-stop stability in simulated live oil environments under various pressures and temperatures.

Phase 4

Certification & Deployment (Future)

Securing necessary industry certifications (e.g., ATEX, API) for hazardous operation and initiating pilot deployment with key industry partners.